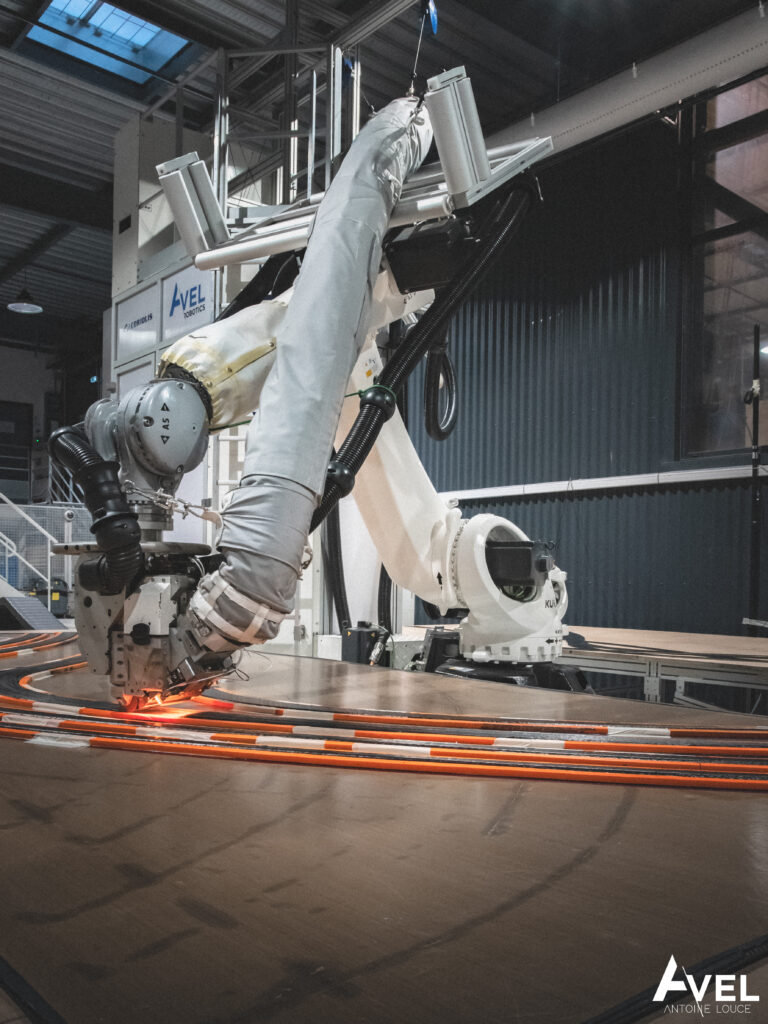

Avel is your partner to design, produce and test your composite parts made of many materials including carbon, glass, aramid, thermoset, thermoplastic, or bio-sourced materials

- Material characterization and testing

- Engineering design, Finite Element Analysis

- Build-to-print manufacturing

- AFP programming

- Advice on starting AFP production, polymerization control, assembly processes

- Advanced control and testing methods

- Performance monitoring

Avel also supports you in industrializing your innovative projects!

Do you want to automate your processes? Avel offers support in choosing the automated means and materials best suited to your needs.